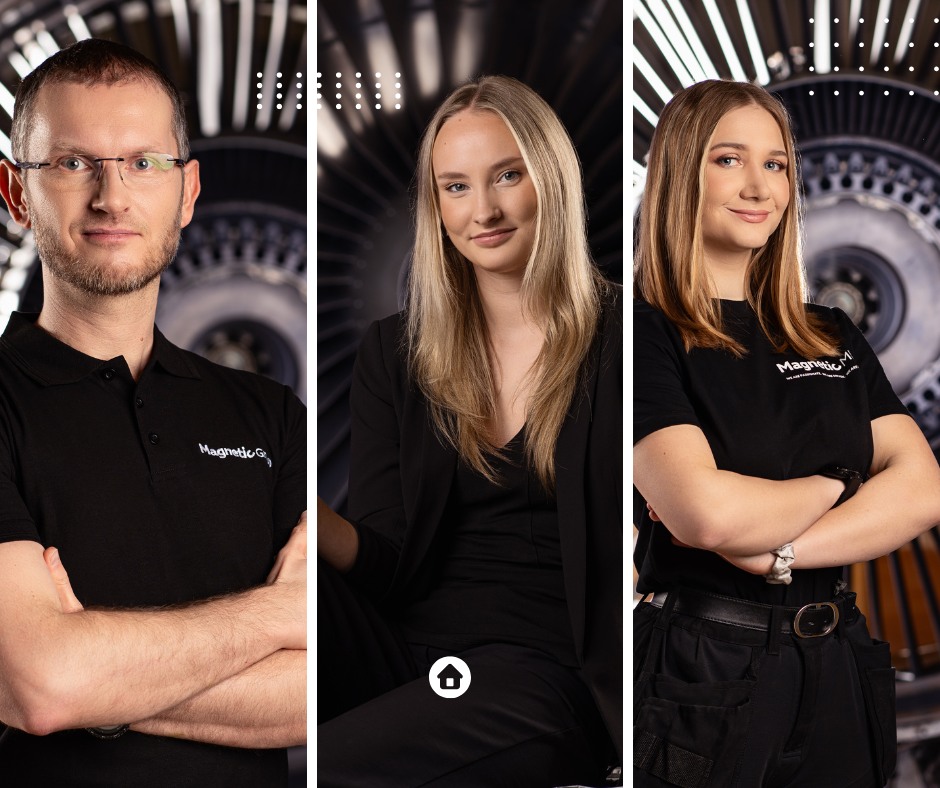

Meet the Team: Slobodan Marinkovic

The drivers of Magnetic Group’s success are our passionate people. Today, we are sitting down with Slobodan Marinkovic, the Magnetic Engines Workshop Manager, who has been leading the Workshop for seven years. When Slobodan speaks, you listen – with over 40 years of experience maintaining aircraft engines, it’s hard to find people with more extensive knowledge than he has acquired. In this interview, Slobodan talks about his career, and gives advice for aspiring aviation professionals.

When and how did your passion for aviation start?

Slobodan: My passion for aviation started by accident. After elementary school and two years in high school, which I found incredibly boring, I sought a suitable technical school to continue my education in 1981. At that time, there was a huge list of available technical schools in former Yugoslavia, and my first choice was a shipbuilding school.

Luckily, after a long discussion with my sister, who proposed aviation school, I decided to proceed. It offered all the required subjects and interesting subjects, such as thermodynamics, aerodynamics, math, physics, and fluid dynamics.

How many aircraft engines do you think you have worked on in your career by now?

Slobodan: Honestly, I haven't counted, but roughly combining engine repair (disassembly/ assembly/ inspection/ BSI), it's likely between 2,500 and 3,000. The number includes various engine types like:

· Pratt & Whitney: JT8D-9/11/17, JT3D, PW120/124/127

· CFMI: CFM56-3/5A/5B/7B, LEAP 1A/1B

· GE: CF6-50/80, CF34

· IAE: V2500

· APU: APS3200 and 131-9A/9B

What have been the biggest changes in the aviation industry during the time you’ve been working in the sector?

Slobodan: Certainly, the most dramatic technical development in my focus area has been in JET/FAN engine midsize design. From the "old school" Pratt & Whitney, Snecma, and Rolls-Royce engine designs to the more advanced CFMI and IAE engines that started to develop in the early '80s, the technical approach to engine exploitation and maintenance has dramatically changed. New modular designs have provided much more opportunities for operators and engine overhaul workshops.

What have been the most memorable moments or projects in your career?

Slobodan: One of the most memorable moments was when MTU Maintenance Vancouver offered me a position to support the new CFM56 production line in 2001. I had a dilemma about whether I was experienced enough (after 17 years in the engine shop) to support such an important and respected company.

Fortunately, I realized my experience was sufficient and acceptable to my new employer. That one year at MTU greatly impacted my career, allowing me to learn more about the internal processes and organization of an engine shop.

What little things do you enjoy most in your line of work?

Slobodan: Borescope inspection is very relaxing and enjoyable for me. It's not as simple as many think, but it's an excellent tool for inspecting the entire engine's internal condition and providing detailed information to customers. After 40 years of experience, it's relaxing for me.

What advice would you give to someone who’s thinking about a career in aviation and Magnetic Engines?

Slobodan: If you like the aviation business and engines in particular, you should consider joining Magnetic Engines. Being a part of Magnetic Group, Magnetic Engines focuses on aircraft engine maintenance. Our dedicated workshop in Tallinn is constantly growing, focusing on engine repairs, technical consultancy, and inspections.

As we’re one of the fastest growing business units, specialists are welcome to apply and join the team. A technical background is essential if you're considering joining us. Without it, it will be tough to understand aircraft engine design and operations. The work will definitely be challenging. You can anticipate a lot of learning in areas like thermodynamics, aerodynamics, math, physics, and fluid dynamics. The work will be challenging, but also rewarding.

go back

go back