Ground No More: Boroblending a Cost-saver Solution for CFM56 Family Engine Compressor Repairs

How to avoid AOG situations and high-cost alternatives when an aircraft engine needs a repair? In some instances, the earlier scenarios are unavoidable, but more cost-effective and easier solutions, like boroblending can suffice. Boroblending helps with engine blade repair when damaged, such as missing tip corners, cracks, dents, nicks, or tears are detected.

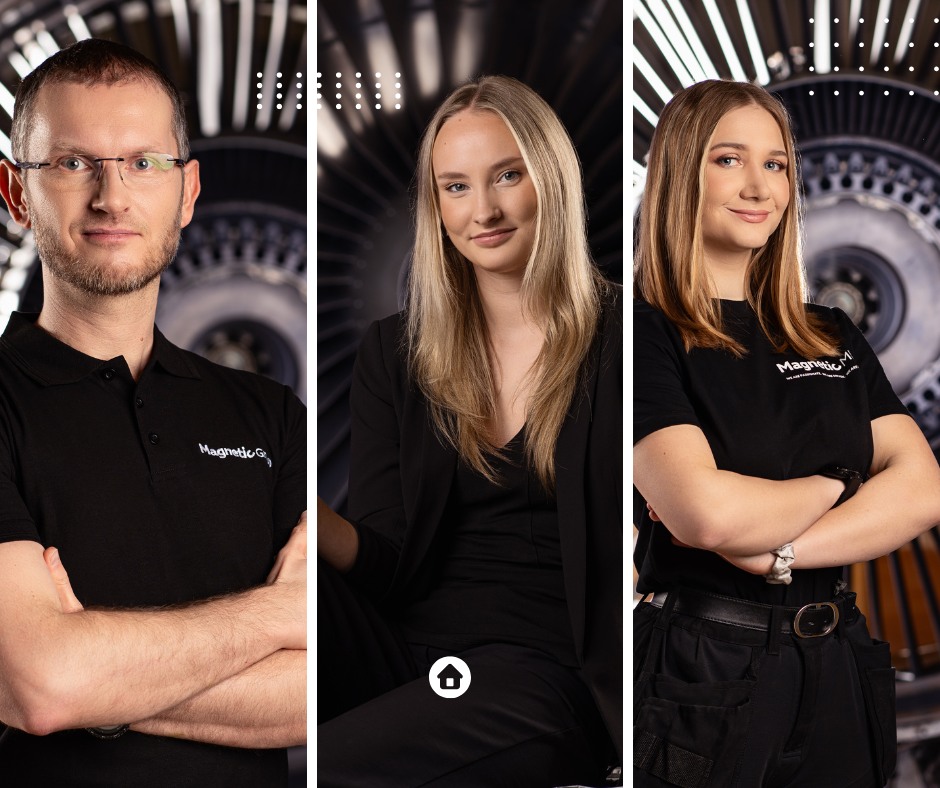

For almost a decade, Magnetic Engines has supported customers by providing boroblend services. A boroblend expert, Ilja Manusha, Engine Workshop Supervisor, takes us through the technique and its use cases in more detail.

What is boroblending, and when is it used?

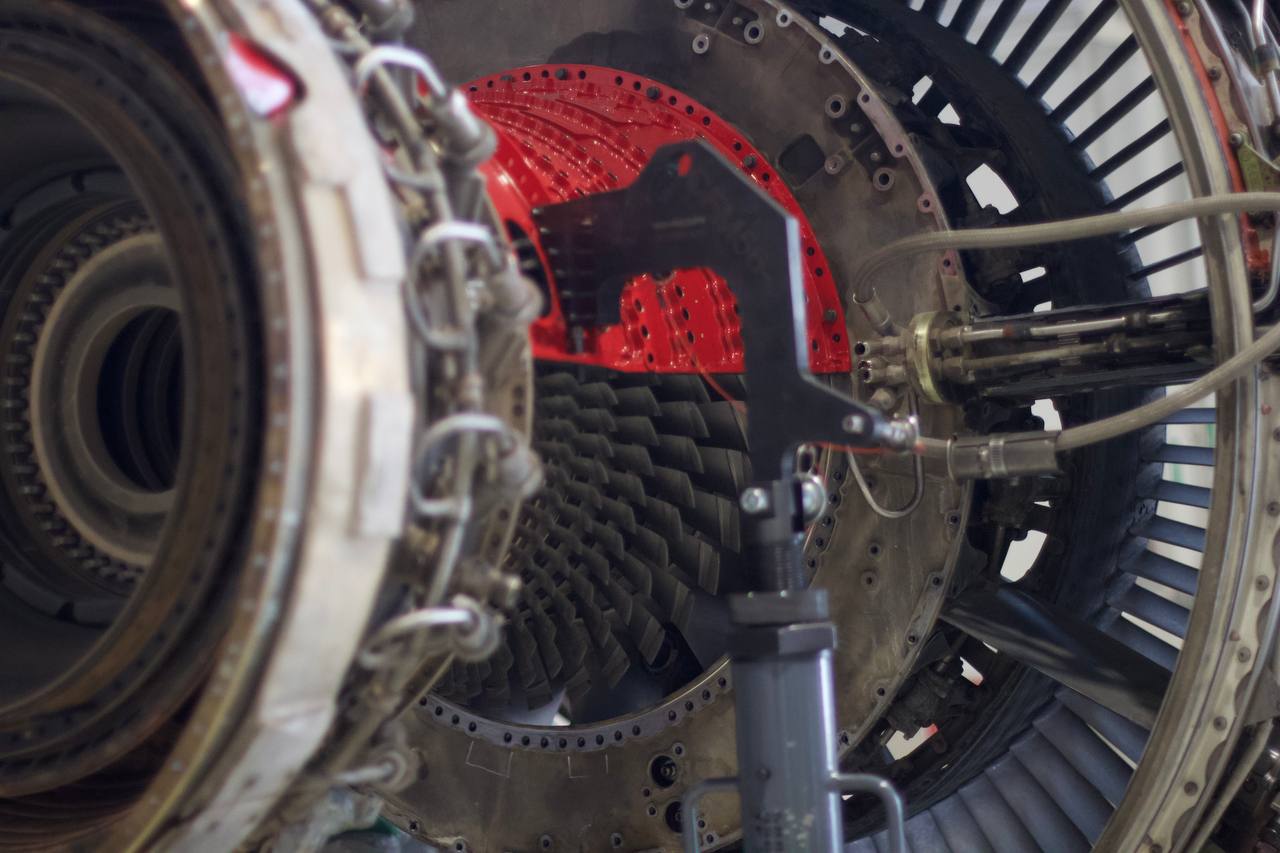

Boroblending is an engine compressor repair technique adopted to prolong the serviceability of gas turbines applicable for the CFM56 family, with the help of detecting blade damages induced by domestic or foreign objects. If such damage exceeds the acceptable limit, the engine could result in inflight shutdown and be sent to the workshop for maintenance or at least top-case repair.

Boroblending could solve this problem through mechanical repair of damaged compressor blades. It is done using grinding and polishing techniques. What is great is that the engine does not require removal, so instead of grounding an aircraft for the week and sending the engine to a workshop, boroblending could be performed in a few hours and cost much less. As a procedure, it could prolong the engine's safe usage and allow service until the next scheduled shop visit, where such blades will be replaced or even left as is.

Sounds like an effective solution. Are there any challenges to consider when using boroblending?

Imagine that a damaged blade was detected during a high-pressure compressor borescope inspection. As the next step, an inspector must measure the damage and determine if it is serviceable, unserviceable, or can be repaired using boroblend techniques. If it is repairable, using a boroblend tool, a specialized mechanic can perform this repair.

All instructions and dimensions are stated in AMM (Aircraft Maintenance Manual), so they should strictly follow the procedure. After the repair is completed, using borescope equipment, the inspector can confirm that the repair was completed within the limit and the engine is back in operation without any restrictions. In a nutshell, you need adequate knowledge and practice to apply boroblending, considering it involves work on a multi-million asset.

Could any mechanic or engineer perform Boroblending? What is essential to know?

There's no 100% bullet-proof answer, as it depends on quality procedures—similar case to using the borescope. The blending procedure is stated in AMM, like borescope inspection, so from one side, any mechanic can do it. But from another side, those procedures require special training and skills; in this case, the short answer is no.

What if you've passed training, but last used your skills a while ago?

There are no special regulations about that, so you have to use your personal judgment and expertise. If you didn't train or perform repairs for a long time, you will likely lose your experience, and we would advise you to perform refreshment training. There is a dedicated boroblending training in our organization to maintain qualifications.

Who could ensure the quality of work performed?

It depends on the capability of a mechanic or specialist. For example, I have the capability to perform borescope inspections and boreblend repairs. So when I come across a damaged engine, I inspect the blade damages, take measures, and then complete the repair.

Once that's done, I take the final measurement and issue EASA Form 1. But sometimes, it can be 2-3 different people. 1) A borescope inspector, 2) a mechanic who will perform the boroblend repair, and 3) a specialist who will certify the job and release the engine to service.

How long do you perform Boroblending?

It all depends on how many blades are damaged, how heavily, and what kind of damage. Let's say one blade repair will take 1 to 3 hours of blending, depending on the damage. Also, add here 1 hour for taking measurements and 1 hour for finalizing paperwork. So for one blade, it takes around 5 hours of work to complete on average.

Are there any specifics varying from engine to engine, or once you know how to perform it on one engine, could you apply it to the rest?

Practically everything is the same; the procedure is identical for all high-pressure compressors on CFM56 engines. The only issue is the borescope port location and the engine environment (the aircraft is outside or inside the hangar). It is important to take into consideration cold or bad weather conditions. And, of course, time pressure sometimes in case you have a tight delivery date.