Eigirdas Keblikas: Implementing the lean approach in an MRO organization

The lean approach has been embraced by many industries, especially due to the benefits it brings. Among them are reduced costs and simplified operations, to name a few. Eigirdas Keblikas, VP of Magnetic Trading, shares his take on how the lean mindset helped navigate the challenging times in the market and served as a catalyst for new ventures.

Question: What has caused this shift, requiring a new business approach?

Eigirdas: It's no secret that the success of an airline or other fleet operator requires having as many aircraft as possible in full operation. In simple terms — an aircraft grounded for repair is not bringing in money. The same goes for an aircraft, taking up space in a hangar or repair facility. With MRO operations accounting for 15-18 % of an airline's total operating costs, profitability is directly affected by repair and maintenance costs, so controlling these expenses is crucial.

For these reasons, airlines and other fleet operators are turning a critical eye on their maintenance and repair operations, looking for ways to cut costs while getting aircraft back in the air faster and more safely. That's why we saw the need to be ahead of the client's needs and adjust our business.

Q: What are some key contributors impacting the need for a leaner model?

E: Cutting costs does not mean going for the cheapest option. Per every maintenance event, there are two important factors to consider when cutting your cost as an operator. First off, it is quality. Not questioning any poor maintenance work will result in AOG situations which, as we all know, will be way more costly in the long run.

The second is efficiency. Sometimes negotiating for man-hours can take weeks, and then once the customer decides to proceed, there's a risk of not having enough time to deliver the unit on time. Imagine if an aircraft stays an additional day in the hangar, or LDG will be delayed by a week because of poor planning. The sum will likely inflate from tens of thousands to 100-200K. So, precise planning and choice of partners become the key to saving your cost.

Q: How has it affected the way Magnetic Group operates?

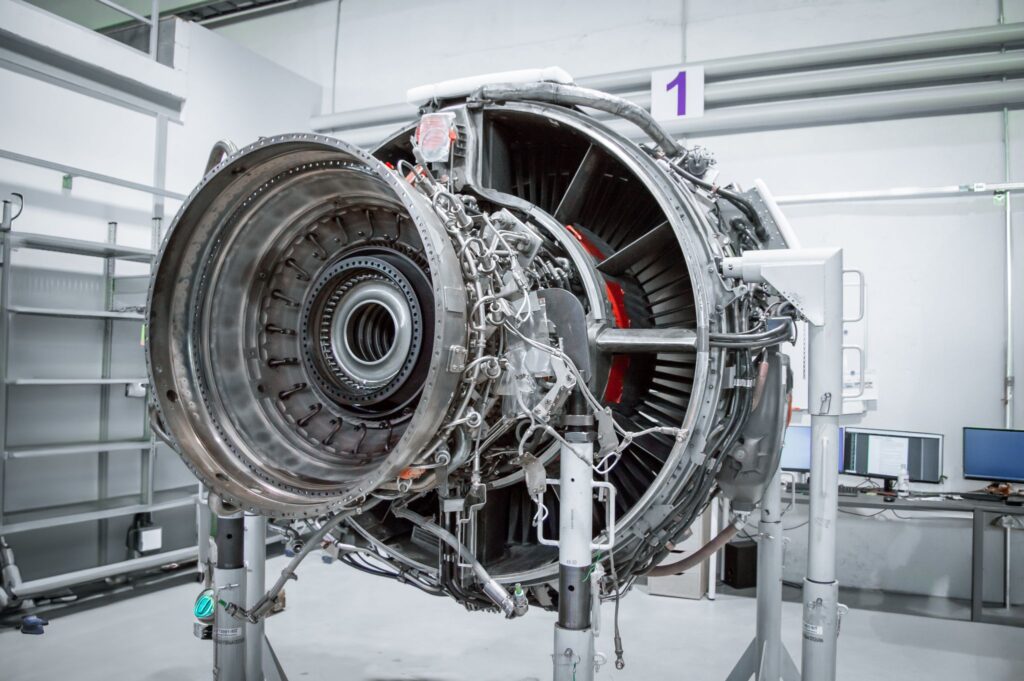

E: When Magnetic MRO was just starting as a separate brand, it was a base maintenance facility in northern Europe. What did we offer? Comparatively cheap labor and high-quality help for airlines in their maintenance events. We were around a 20M$ revenue company with 3 slots for narrow bodies' base maintenance.

Today, this is only one of our business units, which generates approximately 25% of our total revenue. All of this has resulted from our focus being placed on differentiation and adapting quickly to ever-changing clients' needs.

When talking about our services, we no longer provide only MRO but a one-stop solution for all airlines and asset owners. It is clear that aircraft owners are not actually looking for the cheapest option. Instead, they are looking for a complete and fast solution, whether it's only to fix a small avionics part or overhaul the landing gear.

You can have your hangars well-loaded, making the process leaner and more efficient. Still, if you want to attract attention and take a larger slice of the 80-billion MRO industry pie, you should also consider providing an extended range of services. For this reason, Magnetic Group has grown to a company with 10 business units, including line and base maintenance, design and production, spare parts and components solutions, among others.

Q: What role has Covid-19 played?

E: Since 2020, the aviation industry has faced unprecedented change, instability and shock, which has rippled throughout the entire sector—from flight restrictions and quarantine regulations to complete state-wide commercial shutdowns. It was probably one of the biggest challenges for the whole industry in its entire history.

From the company's perspective, we had to take some very aggressive cost-cutting measures right at the beginning. However, we were never thinking about how to survive but rather how to emerge from the chaos on top. Canceled orders from airlines have had their effect, but a new trend for leasing aircraft has also provided new customers and opened untapped markets.

Consequently, due to the turmoil caused by the pandemic, the industry and customers pushed for a new service model. Compared to other sectors, where they have been adopting a similar lean model for years. This was also how our total asset management program for landing gears and APUs was born.

Why acquire and store engine stands when you can lease them? The same goes for landing gears, APUs or components’ pools, especially when you can also receive engineering and consulting services. For example, if you are a small airline with 5 to 10 aircraft, we can take care of your asset management entirely from A to Z.

So, in a steady and established industry like aviation, airlines have started to prioritize and seek new ways of operating, particularly to become leaner. Therefore, they do not and should not hire large quantities of in-house engineers or big repair management teams. Instead, they should focus on flying more than ever.